| |

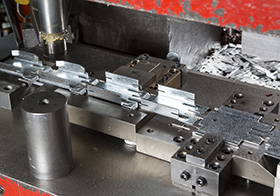

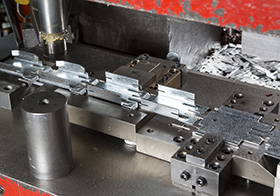

Leefson provides precision metal stampings and assemblies from short, medium or long runs for a wide range of industries, including:

Engineering:

Engineer, design, build, modify dies and tooling

Autocad, Solidworks and Mastercam are used in the design process

Design and planning assistance available

Quality Control:

Monitors part production using SPC hardware and software as the industry standard for measuring and controlling quality during the manufacturing process

Quality and inspection checks per customer requirements

Wire EDM and CNC Machining:

Precision punches, die blocks, inserts, gauges, prototypes, jigs and fixtures

3 axis vertical machining centers for precision 2D and 3D parts

Bob CAD v26 and Esprit - programming & communication software

Tool and Die - Machining:

Full machine and tool & die shop which includes milling machines, surface grinders, drill presses, tapping machines and lathes

Pennsylvania state approved tool & die maker apprenticeship program

New dies - blanking, forming, coining and progressive dies available with automation such as in-die tapping, pneumatics & sensors

Die repair and rebuilding

Heat treating, precision grinding & honing

Press shop:

Single hit presses, coining presses and automatic punch press lines

Assembly:Screw, spring and rivet installation of multi-part assemblies

Pem fastener installation system and other secondary operations

Finishes:Powder coat and conventional paint finishes

Chemical conversion and anodized process finishes

Chromate plating in various colors

Tin zinc mechanical plating

Long term rust inhibitor coatings

Degreasing, deburring and burnishing

Special services:

Packaging per customer requirements

Local delivery available

|

|

|

|